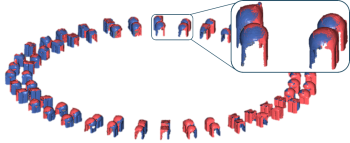

Classification system for hairpins

Senswork's solution combines a high-resolution, rotary multi-camera system based on laser triangulation and advanced deep learning architectures for 3D data.

The increasing electrification of vehicles requires new manufacturing approaches for electric drives. Modern winding concepts such as hairpin, I-pin or X-pin technology use rectangular copper wires that are connected by laser welding. The quality of these spot welds is crucial for the performance and reliability of the engine. Senswork's solution combines a high-resolution, rotary multi-camera system based on laser triangulation and advanced deep learning architectures for 3D data. The company combines many years of integration experience with its intensive industrial research and transfers a non-destructive 3D inspection method into a high-performance, industry-ready inline process.