Glass vial inspection system VRI

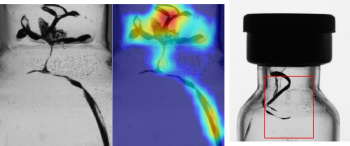

The Antares Vision AI-based visual inspection system detects cracks on the neck and shoulder of glass vials, overcoming the limitations of conventional image processing systems.

The solution identifies real defects by detecting anomalies, while reducing the frequency of false positives caused by droplets that a conventional machine vision system cannot distinguish. The analysis is based on 16 images per sample, which are processed by an AI model trained on hundreds of images to ensure reliable and accurate quality control.